The textile industry is my country’s traditional manufacturing industry and an important basic industry for people’s livelihood. As an indispensable and important part of the textile industry, the printing and dyeing industry has played a huge role in promoting the rapid development of my country’s textile industry. However, it also has problems such as large amounts of wastewater and pollutant emissions and high treatment costs, and it is in urgent need of upgrading. promote.

The pre-treatment process of printing and dyeing fabrics is the basic process of the printing and dyeing production process. The traditional pre-treatment process of printing and dyeing requires the use of a large amount of chemicals, which not only increases the difficulty of controlling the production process, but also faces oxidation holes, insufficient whiteness, and strong damage. , low hair efficiency, rough feel and many other stubborn problems.

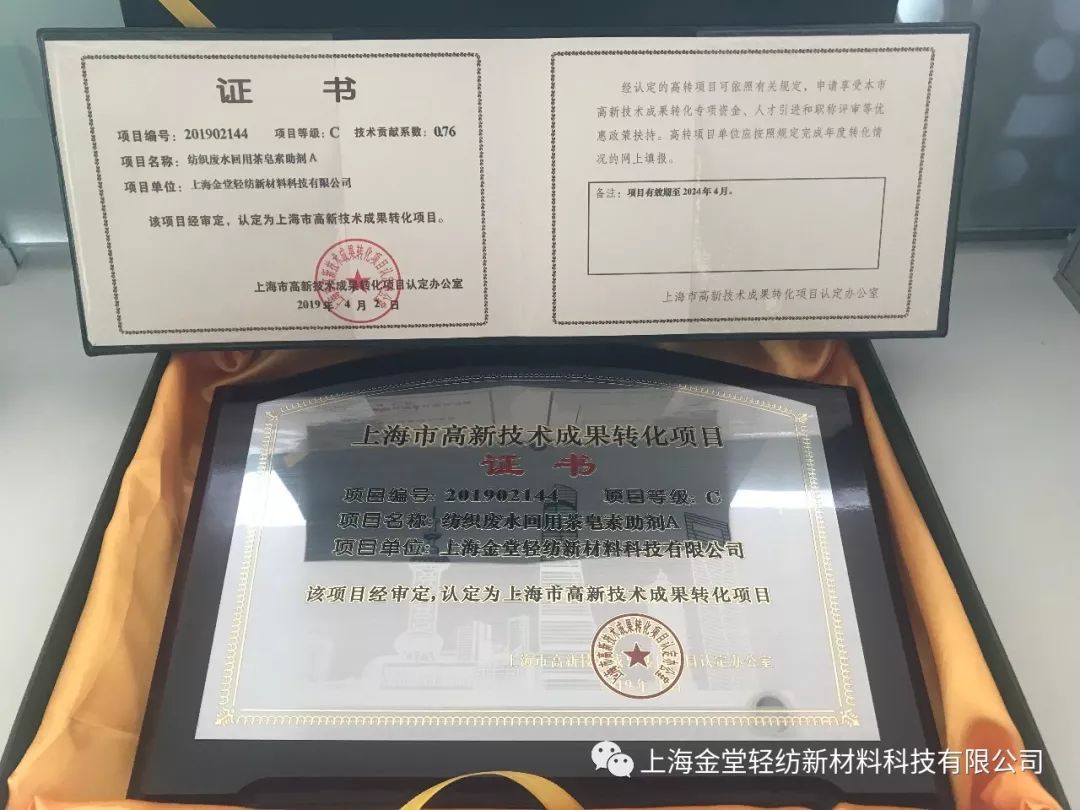

In order to solve the stubborn problems in the pre-treatment of printing and dyeing fabrics and promote the healthy, green and sustainable development of the printing and dyeing industry, Shanghai Jintang Textile New Material Technology Co., Ltd. has been sharpening its sword for ten years and successfully developed the Bu Gong tea saponin additive. Recently, it was awarded the second batch of Shanghai high-tech achievement project certification in 2019.

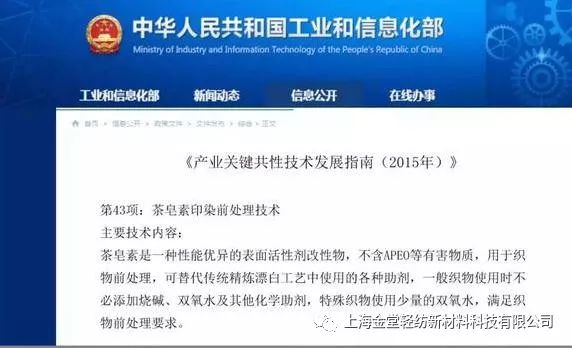

It is understood that the new textile printing and dyeing pre-treatment auxiliary “Bu Gong Tea Saponin” developed by Shanghai Jintang Textile New Material Technology Co., Ltd. uses nano titanium oxide TiO2 as the carrier to carry out the treatment of the natural plant surfactant tea saponin. Modification produces a high degree of catalytic efficiency, increasing the reaction speed by more than 100 times. It can quickly hydrolyze oils, waxes and impurities on fabrics, remove cotton seeds and lignin, restore the original white color of cotton fibers, and improve the scouring of fabrics. , bleaching and dyeing are completed in the same equipment and the same treatment solution. Data shows that using the short-process process of Bugong tea saponin can achieve energy saving and emission reduction by more than 50%, and reduce the comprehensive cost of traditional printing and dyeing enterprises by 20% to 50%.

Currently, Bugong tea saponin is suitable for pre-dyeing treatment of cotton, linen, polyester-cotton and blended gray fabrics. Especially for towel gray fabrics, it can be scoured, bleached and dyed in one bath, which not only shortens the process and saves water, electricity and steam costs , and improves product quality, increases fiber strength, saves energy and reduces consumption, and can realize the recycling of all pre-treatment water for printing and dyeing, complete wastewater treatment during the production process, control pollution at the source, and prevent pollution transfer.

In order to better upgrade products and effectively meet market and customer needs, it is reported that this process technology has been running continuously for at least 30 months in many companies such as Vosges Group Co., Ltd. and Dongdu Textile Group Co., Ltd. Facts show that The process quality is stable, and the pre-treatment effect meets and exceeds the original traditional process. All pre-treatment waste water is recovered and continuously recycled, so no waste water discharge can be achieved. The promotion of this technology has received strong support from IKEA Trading Services (China) Co., Ltd.

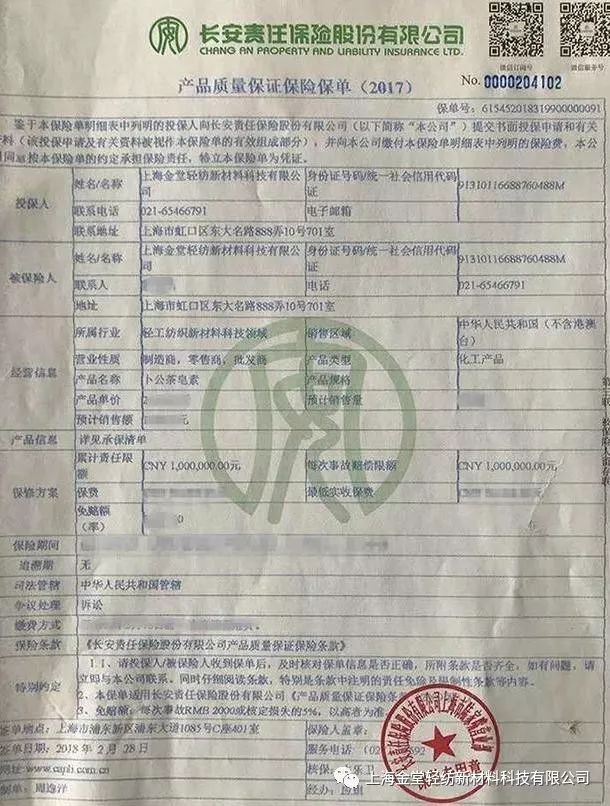

As a technology company specializing in the research and development of green and environmentally friendly new materials in the textile printing and dyeing industry, and providing overall energy-saving and emission reduction solutions for the entire textile printing and dyeing process, Shanghai Jintang Textile New Material Technology Co., Ltd. has successively obtained the EU ECO-PASSPORT (Chemical products, auxiliaries, dyes) ecological product certification “Ecological Textile Passport”, Chang’an Insurance Company’s million-dollar quality insurance, etc. This high-tech certification also strongly proves that the company is committed to energy saving, consumption reduction, and green production for printing and dyeing. The important role of corporate escort.