China's paper industry is facing environmental pollution problems caused by the lack of water resources and wastewater discharge, which are seriously restricting the development of the industry. It has become an industry consensus to develop pulping methods with less or no wastewater discharge.

Plastic-free environmental protection is also becoming a global trend in the packaging industry, and the demand for paper continues to expand. The existing process needs to be more environmentally friendly. "A lot of grass and a lack of wood" is an objective factor for the development of China's paper industry to use non-wood fiber as the main raw material for production. It is particularly important to protect forests, maintain ecological balance, and vigorously develop wood substitutes and non-wood fiber pulping.

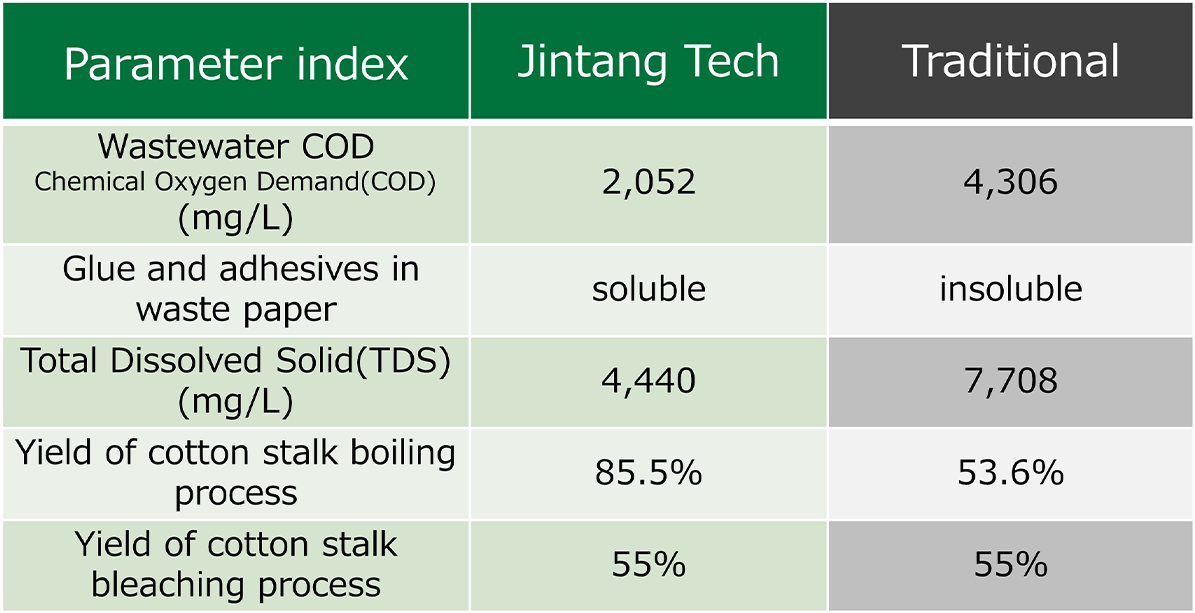

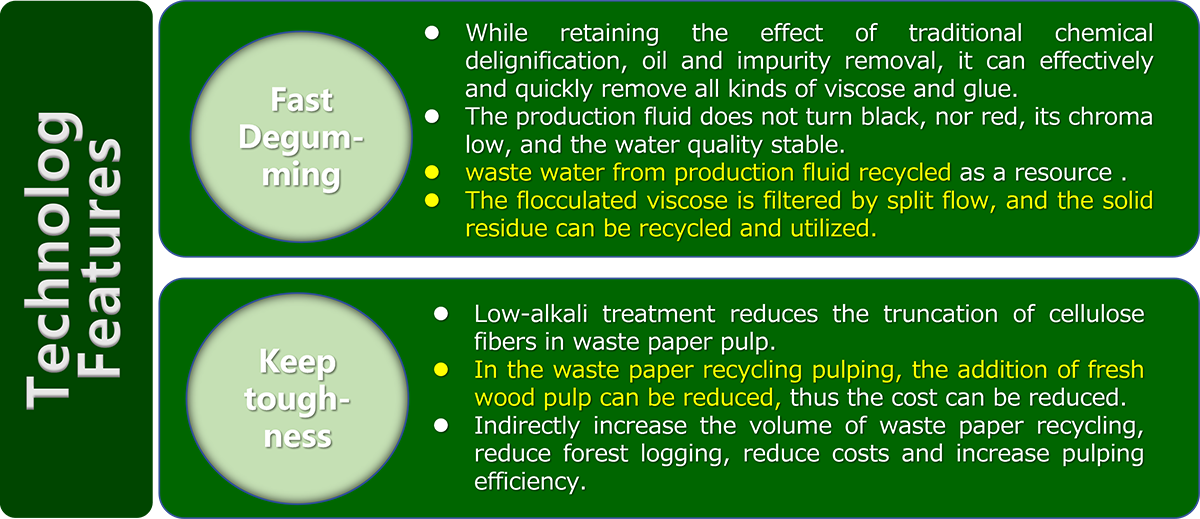

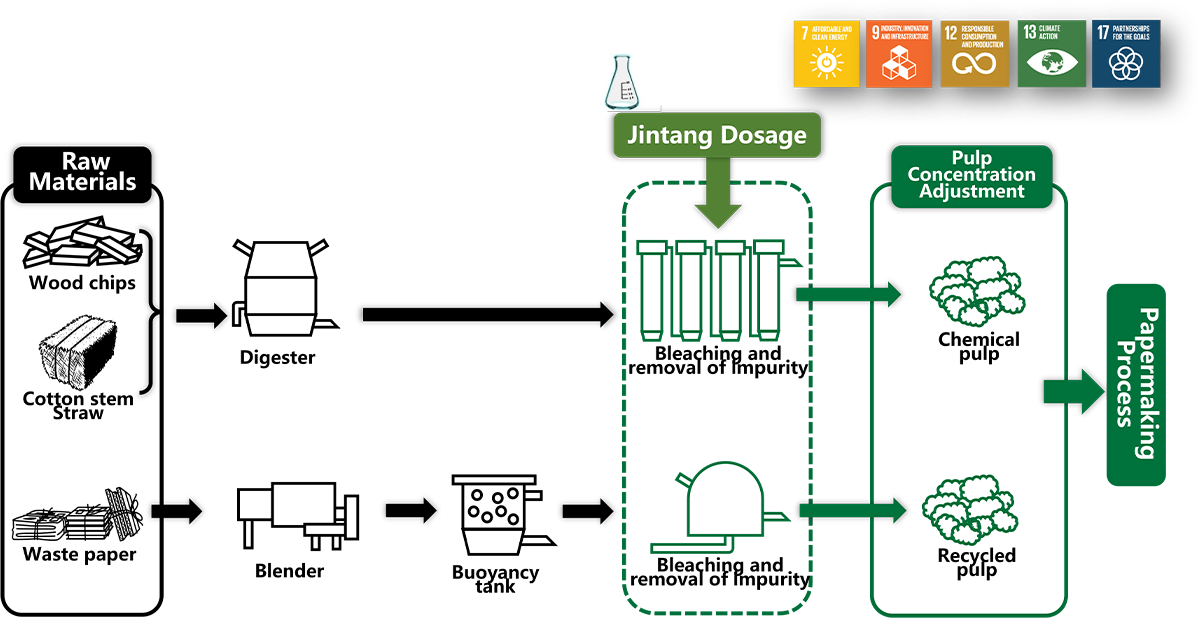

Jintang technology realizes zero discharge of wastewater from pulping pretreatment. Suitable raw materials include wood, waste paper, and herbs. In the recycling of waste paper, the production of stickies can be suppressed, and the quality of pulp, pulping rate and production efficiency can be improved.

1. Adhesive sticky

At present, imported waste paper such as American waste, European waste, and Japanese waste is often used as raw materials in papermaking and pulping in my country. Although it is green and environmentally friendly, one of the main obstacles in the pulping process is the problem of stickies. During the papermaking process, it adheres to the felt, forming wire, drying wire, etc., causing obstacles to the operation of the paper machine.

2. High consumption and low efficiency

Cotton stalks have the characteristics of longer phloem fibers and shorter xylem fibers. Cause not only consume a large amount of medicines when pulping, increase cost, increase the weight of pollution.

Original equipment:

Apply the simple and direct adding method without changing the original equipment

Replace caustic soda:

No need to add caustic soda, hydrogen peroxide and other chemical additives, shortened

process with only one dosage

Containing ingredients:

No NaOH (caustic soda), APEO (Alkylphenol Ethoxylates Ethyl ether) and other hazardous

substances, rapid dilution with water in any proportion

Effectiveness:

Quickly remove lignin, pectin and other substances in cotton stalks, etc., reduce raw fiber

damage and improve pulp quality and complete the pulping process under low alkali conditions

with high yield