Company News

Breaking News | Shanghai Jintang Bugong Tea Saponin is included in the “National Catalog”

time:2024-01-31 visits:736

On October 25, the “Catalogue of Industrial Water-Saving Technologies, Technologies and Equipment Encouraged by the State (2019)” (hereinafter referred to as the “National Catalog”) jointly organized by the Ministry of Industry and Information Technology and the Ministry of Water Resources was concluded. After a publicity period lasting nearly half a month, it was officially released, and Shanghai Jintang Bugong tea saponin pre-treatment technology for printing and dyeing was included.

This big news is another milestone in the development of Shanghai Jintang’s ten-year independent innovation technology, laying an important foundation for completely opening up from the technology end to the market application end.

It is understood that the “National Catalog” has always been recognized by domestic and foreign enterprises, industries, markets and consumers as an authoritative and directional national note, and is a reliable driving force leading the development of the industry.

The “National Catalog” was formulated for the purpose of accelerating the promotion of efficient industrial water-saving technology, guiding green production and consumption, and improving industrial water efficiency. It was recommended by relevant units, expert review, public announcement and other strict procedures. Final release.

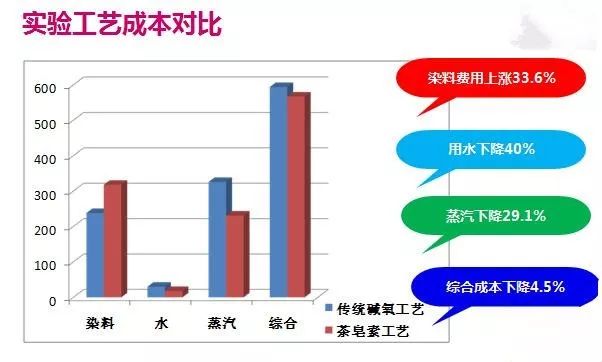

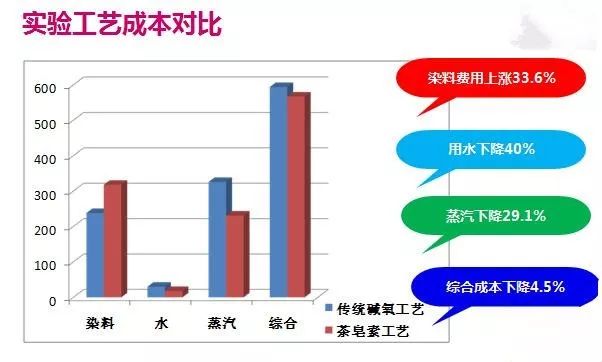

The catalog identifies that the “Bugong tea saponin” printing and dyeing pre-treatment technology uses a surface-active modified substance with excellent performance – tea saponin, which isused in textile pre-treatment and can replace the traditional refining and bleaching process. Various additivesused in.

When using general fabrics, there is no need to add caustic soda, hydrogen peroxide and other chemical additives. Special fabrics use a small amount of hydrogen peroxide to meet pre-treatment requirements, which can save 15% to 20% of water compared with traditional processes.

In this regard, Zhang Zhijun, chairman of Shanghai Jintang Textile New Materials Technology Co., Ltd. and one of the inventors of the patented technology of “Bugong Tea Saponin” pre-printing and dyeing treatment, believes thatthe value of technological innovation enterprises lies in whether they can provide services for the entire The industry creates the future.

Shanghai Jintang has focused on one thing for ten years with the spirit of craftsmanship. The independent innovation technology research and development has now entered the technological maturity stage and has begun to rapidly advance from the technology end to the market application end. In the future, it will no longer be limited to the pre-treatment stage of printing and dyeing, but will achieve widespread application breakthroughs in water-saving technology innovation in dyeing and printing and other production links.

Being able to achieve this step is all due to the national energy conservation, emission reduction, green development and environmental protection policies pointing to the general trend, as well as the huge market potential space formed by the traditional enterprises’ own transformation and sustainable development requirements.

Our corporate development philosophy is to focus on technological innovation while paying more attention to serving the four core concerns of traditional enterprises seeking transformation and sustainable development:

-

1. Product quality – Enhance corporate brand value;

-

2. Production efficiency – Optimize labor costs;

-

3. Comprehensive cost – Simplify the process to save energy and reduce consumption;

-

4. Environmental protection and sustainable development—Meeting standards and producing green products creates social value.

This is also the more profound significance for our company that the printing and dyeing pre-treatment technology of Bu Gong tea saponin has been included in the “National Catalog”.

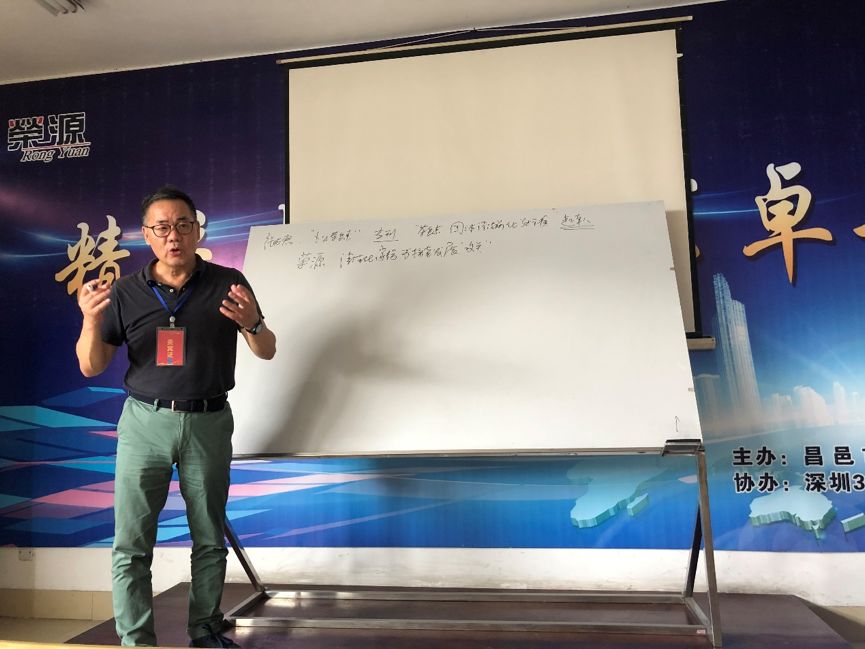

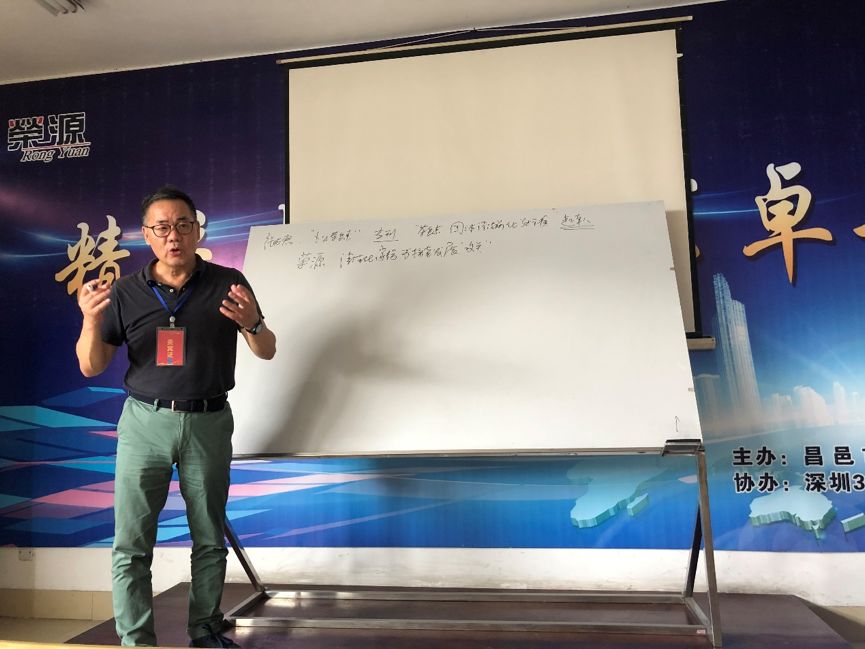

Zhang Zhijun, Chairman of Shanghai Jintang Textile New Material Technology Co., Ltd.

Training and guidance at a printing and dyeing company