Recently, the General Office of the Ministry of Industry and Information Technology organized a launch

Top 100 groups in the industrial communications industry in 2019

Standard application demonstration project application work

Tea saponin compound auxiliary for Shanghai Jintang textile pretreatment

Meet all the conditions involved in the application and plan to participate

It is understood that the application for hundreds of group standard application demonstration projects requires associations, federations, societies, chambers of commerce, and industrial technology alliances with legal personality (hereinafter collectively referred to as social groups) to formally publish and implement group standards in the industrial field.

The applied group standard application demonstration project should be implemented for at least 6 months (the deadline is August 31, 2019), and the technical level is relatively high and the application effect is good. For >Promote the improvement of quality brands and promote high-quality development of the industryHave a strong leading role, have good systematicity and systematicity, and focus on supporting the application demonstration of innovative, advanced and international group standards.

Shanghai Jintang fully meets the application conditions. Tea saponin compound additives for textile pre-treatment have very obvious advantages in declaration:

-

1. Innovative group standards that fill the gaps in national and industry standards;

-

2. Advanced group standards whose technical indicators are comprehensively stricter or better than existing national and industry standards;

-

3. It has an internationally leading level and simultaneously promotes the development of group standards for international standards.

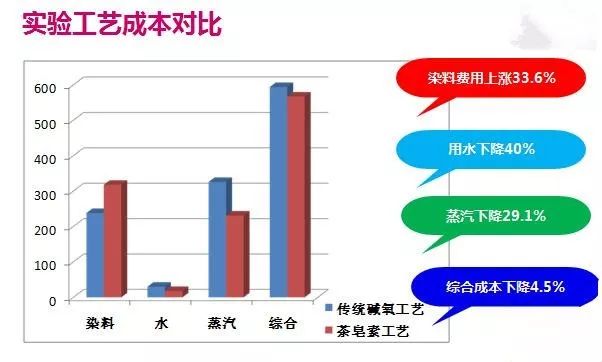

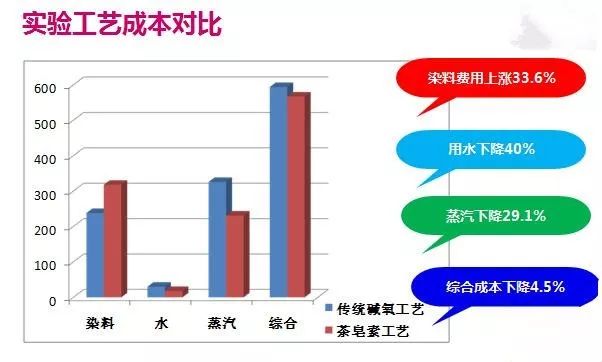

Vosges Group applies this innovative technology to produce 30,000 tons of quilt fabrics per year in a single production line, saving 84,000 tons of water and 21,000 tons of steam annually, and saving 140 yuan per ton of product cost. After using tea saponin compound additives, water can be saved by 53%, steam can be saved by 31.8%, comprehensive costs can be reduced by 30%, and pollution emissions can be reduced by 70%.

According to the application results of the Vosges Group, it is not difficult to find that caustic soda, hydrogen peroxide, and chemical agents are used extensively in the traditional fabric pretreatment process, resulting in “high chemical consumption, high process energy consumption, and wastewater” in the conventional pretreatment process. “High COD concentration” is one of the three high problems. The one-dose scouring and bleaching environmentally friendly pre-treatment additive developed by Shanghai Jintang does not require caustic soda when used. It can meet the requirements for fabric printing and dyeing pre-treatment without changing the original equipment. Various quality requirementsThe recycling of waste liquid can reduce water consumption and eliminate sewage discharge in the production process, saving 80-90% of fresh water.

Zhang Zhijun, Chairman of Shanghai Jintang Textile New Material Technology Co., Ltd.

On-site guidance at Shandong Vosges Group

During the application process, the Bu Gong tea saponin preparation can quickly decompose the oil, wax fat and impurities on the fabric, remove cotton seeds and lignin, achieve good whiteness and high wool efficiency, and meet the fabric pre-treatment requirements.

Zhang Zhijun, chairman of Shanghai Jintang Textile New Materials Technology Co., Ltd., believes that textile pre-treatment is the largest pollutant discharge in the dyeing and finishing process and is a key point affecting product quality. Long process, high energy consumption, and complex processes for various fabrics are the three major problems in textile pre-treatment.

Promote the pre-treatment technology of Bu Gong tea saponin for printing and dyeing, which can make the process simple and meet the application of different equipment. On the premise of ensuring product quality, achieving no wastewater discharge, environmental protection and energy saving effects also creates an important condition for future industrial intelligent upgrading.

The formulation of this standard fills the gap in national standards or industry standards and will regulate the market, orderly competition and promote energy conservation and emission reduction for the application of biomass additives in the textile field. Industry demonstration and benchmark significance.

At present, Shanghai Jintang has achieved zero-emission industrialization before printing and dyeing. It has been certified by three national ministries and commissions and recognized by international brands. It is the 8th China Entrepreneurship and Innovation Competition 2019 Shanghai Division “Entrepreneurship in Shanghai” International Innovation and Entrepreneurship Competition” Excellent Enterprise Award”. Its innovative technology and craftsmanship have attracted the attention of UNESCO.

Award Certificate

Taking a photo with the head of UNESCO