With the industry’s cutting-edge scientific and technological innovation technology at the international leading level, Shanghai Jintang has always been dedicated to building the top-level design of its own R&D technology system.

It is reported that the company’s Bugong tea saponin auxiliary has achieved 10 related projects in the zero discharge process of wastewater treatment before printing and dyeing, and is applying for the Ministry of Industry and Information Technology’s “Technical Guidelines for Green Development of the Printing and Dyeing Industry”.

Shanghai Jintang hopes to use these 10 technological innovation projects in the printing and dyeing industry to become a nationally recognized leader in the green development of the industry.

Technology supports industrial innovation

It is understood that the Ministry of Industry and Information Technology’s “Technical Guidelines for Green Development of the Printing and Dyeing Industry” was formulated based on the fact that the development of the printing and dyeing industry is currently undergoing a shifting period, and the printing and dyeing industry focuses on the new positioning of “technology, fashion, and green”.

The “Guide” continues to deepen the supply-side structural reform, promote the digital, networked, and intelligent development of the printing and dyeing industry, and promote industrial integration and application innovation. It has become a trend and a strategy at the national level.

Among the 10 related projects of Shanghai Jintang Bu Gong Tea Saponin Auxiliary to achieve zero discharge of wastewater from pre-treatment of printing and dyeing, two items, including zero discharge of wastewater from continuous pretreatment of towels and zero discharge of continuous wastewater from knitting, were approved in 2017. The Ministry of Industry and Information Technology has passed the review and approval of the Technical Guidelines for Green Development of the Printing and Dyeing Industry, and the remaining eight projects are currently under actual testing.

Bu Gong tea saponin has been technically approved by the Ministry of Industry and Information Technology

Green, environmentally friendly, economical and reliable

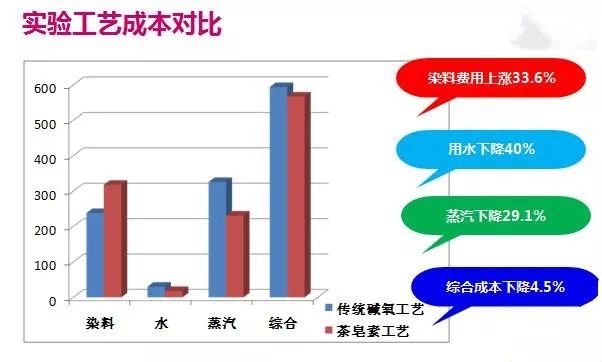

Taking the “Loose cotton pre-treatment without wastewater discharge” project as an example, in the actual measurement in the production workshop of Zhejiang Huafu Fashion Co., Ltd., the traditional alkali oxygen process was compared with the Bu Gong tea saponin boiling and bleaching process, and the results were found:</p p>

1. The strength loss and weight loss rate of cellulose fibers after boiling and bleaching with “Bu Gong Tea Saponin” are lower than those of conventional alkali oxygen boiling and bleaching processes;

2. It feels soft and has good spinnability, which is beneficial to the spinning process and improves the yarn yield and the production efficiency of the spinning mill;

3. Dyeing production efficiency increases by approximately 30%, and comprehensive costs decrease by approximately 12%;

4. The residual liquid after boiling and bleaching with “Bugong Tea Saponin” can be reused after sedimentation and filtration without wastewater discharge; it reduces the usage of clean water and the discharge of sewage, and meets the requirements of green and environmentally friendly production.

Relevant people from Shanghai Jintang said: In recent years, the company’s research and development capabilities have been continuously enhanced and its technical reserves are strong. Building a nationally recognized industry green development standard system is in line with the company’s long-term development goals and strategies.

Patented innovative technology – Bugong tea saponin auxiliary has replaced the traditional boiling and bleaching process and has represented the international advanced level. Its biggest advantage is zero discharge of waste water, which can significantly reduce the cost of water, electricity and steam</strong >, the economic benefits are obvious.

At the same time, more importantly, itreduces the environmental protection burden of enterprises and has obvious social benefits. And just by reducing wastewater discharge and saving wastewater treatment costs, companies can save a lot of money.