In addition, some companies will retreat in the face of interests, or evade the standards; some companies are conservative and subjectively refuse the application of green and environmentally friendly innovative technologies.

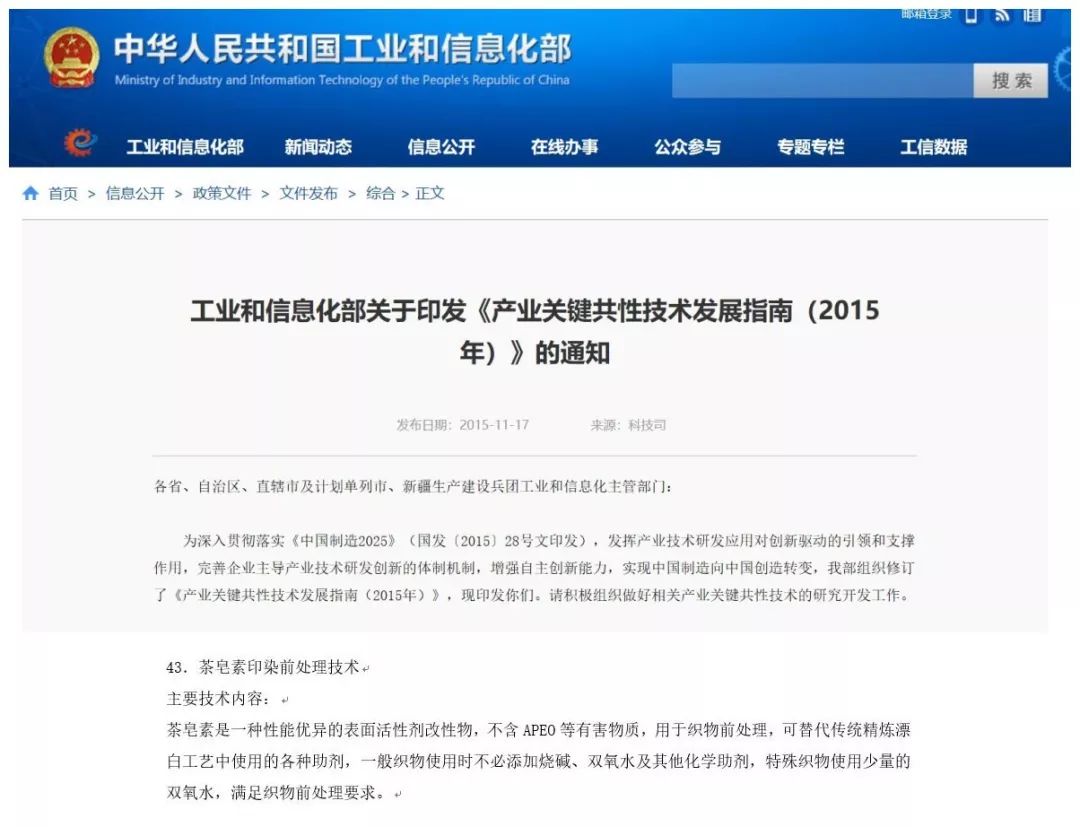

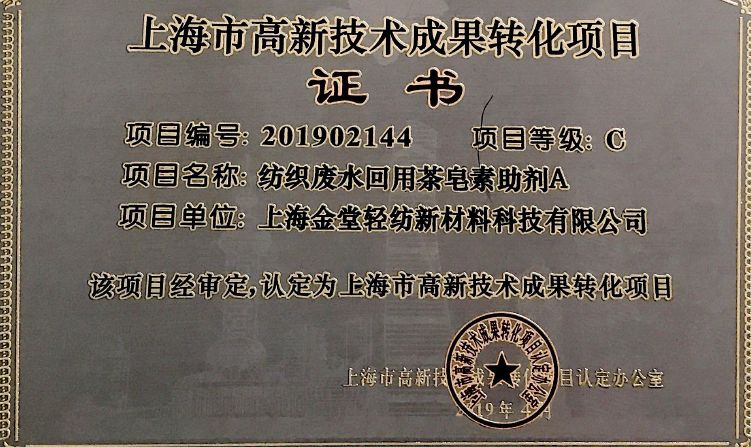

After 9 years of R&D and application of the “New Technology for Zero Discharge of Wastewater in Textile Pretreatment” and “New Technology for Continuous Pretreatment of Fabric Production without Wastewater Discharge”, Shanghai Jintang Light Textile New Material Technology Co., Ltd.from discarded tea Tea saponin is extracted from the meal, and new environmentally friendly additives are synthesized to replace traditional chemical additives such as caustic soda and hydrogen peroxide to achieve zero discharge of wastewater recycling before printing and dyeing.

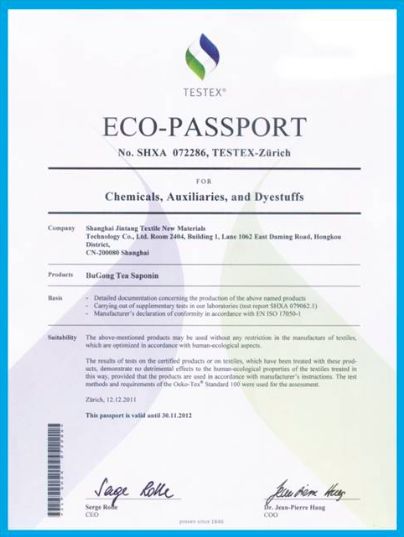

Bu Gong tea saponin haspassed the scientific and technological achievements appraisal organized by the Ministry of Industry and Information Technology, the Ministry of Environmental Protection, and the National Development and Reform Commission organized by the Textile Engineering Society. The appraisal result is: internationally advanced level.

A few days ago, Shanghai Jintang has successively begun to apply for the 2019 “Application Demonstration of Hundreds of Group Standards” and “Technical Guidelines for Green Development of the Printing and Dyeing Industry” projects in the industrial communication industry. 2019 Shanghai Division “Entrepreneurship in Shanghai” International Innovation and Entrepreneurship Competition “Excellent Enterprise Award”), build a “standard” top-level design of its own R&D technology system, and strive to become an industry leader.

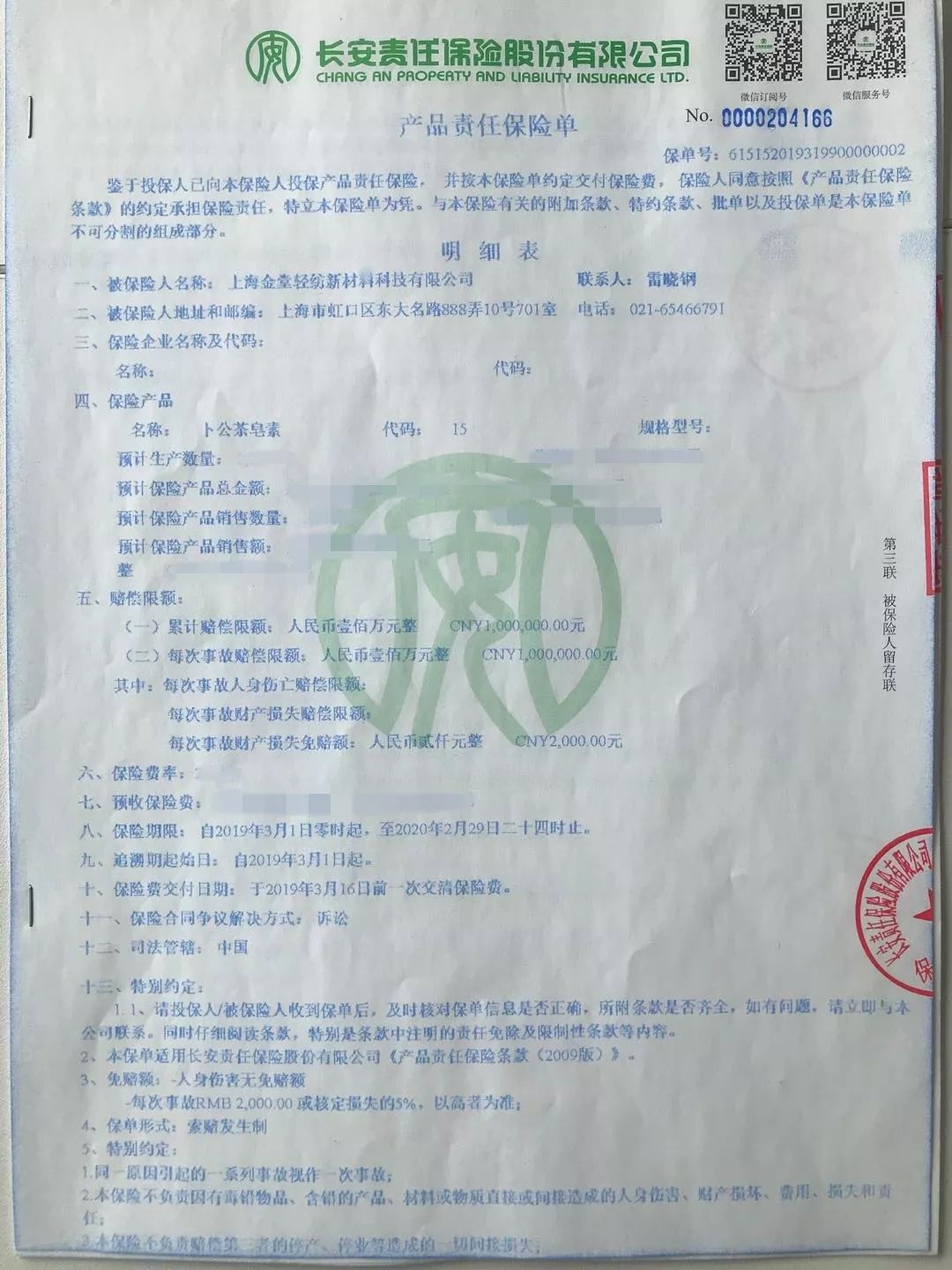

02 million insurance certificate

Shanghai Jintang and IKEA ITTC Asia Pacific Laboratory held a meeting

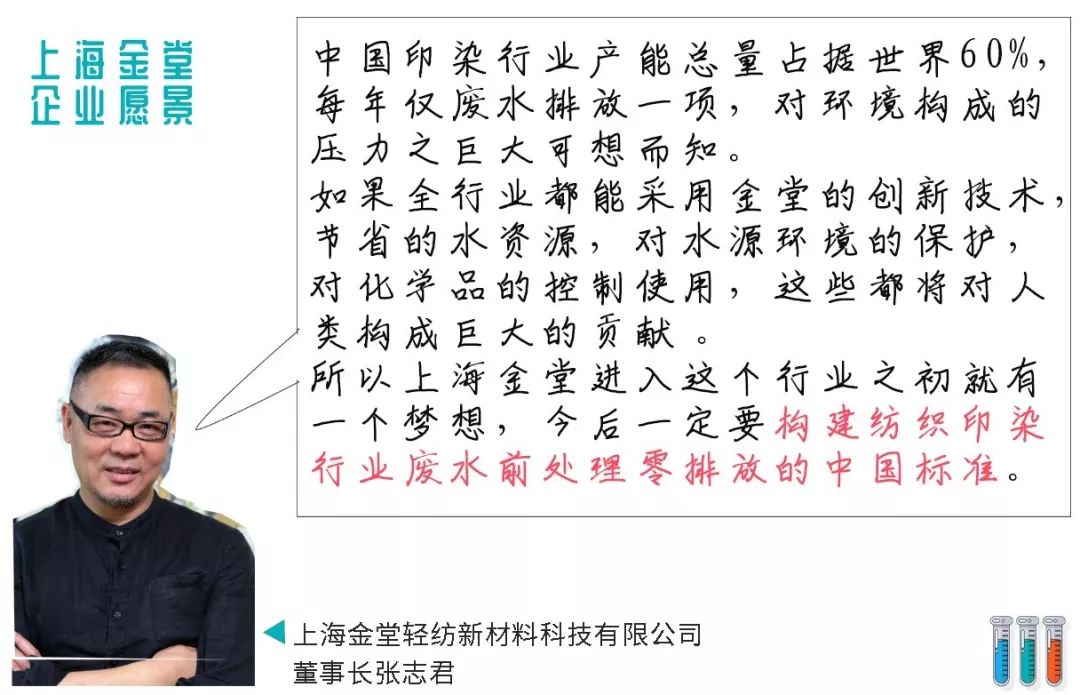

Zhang Zhijun, chairman of Shanghai Jintang Light Textile New Material Technology Co., Ltd., said: “If this technology is widely adopted across the industry, it is expected to save 4.5 billion tons of water, which can meet the annual water consumption of two Shanghai urban residents.</p p>

So the core of all our technologies is based on focusing on environmental factors such as product energy and water consumption, waste emissions, etc. We hope to improve the human living environment and everyone can live a sustainable and beautiful life. This is also what our company should take on. A social responsibility.

We look forward to the day when the relevant processes related to zero wastewater discharge can be extended throughout the entire printing and dyeing production process, becoming a nationally recognized industry standard and even a Chinese standard recognized by the world, truly realizing the goal of green printing and dyeing.”

It is understood that in May this year, relevant people from UNESCO stated that they paid close attention to the innovative technology of Shanghai Jintang Bugong tea saponin auxiliary, expressing the hope that this technology project will promote printing and dyeing and other traditional enterprises around the world to move towards green, The goal of sustainable and high-quality development is moving forward.

Presidents of the New York Association of UNESCO Li Yiling (left) and Zhang Zhijun (right)

Taking a group photo at the United Nations Headquarters