Jintang Textile Printing and Dyeing V 3.0 Process Technology Package System(Hereinafter referred to as textile printing and dyeing V3.0 process technology.) It is a process technology independently developed by Shanghai Jintang Textile New Material Technology Co., Ltd. In 2017, its application demonstration project was jointly identified as “internationally advanced” by three national ministries and commissions. Textile printing and dyeing V3.0 technology has won 16 national patents, obtained a variety of honors, and led the drafting of group standards in the application of multiple scenarios.

Link Jintang Certifications and Honors

Throughout the development process of the textile printing and dyeing industry,Shanghai Jintang believes that the development of the industry can be divided into three stages of system engineering technology.Textile printing and dyeing V1.0, 2.0 and 3.0 three process technologies are applied respectively.

Link to the article “Jintang Zhang Zhijun on the 3 Stages of Printing and Dyeing Industry Upgrading”

Solve the problems existing in the past V1.0 and 2.0 system engineering technology process editions:

1. The alkaline oxygen pretreatment process produces fiber damage, resulting in “oxidation holes” (fiber damage) that cannot be solved.

2. A large number of low polymerization returns, causing product quality problems.

3. The hardness of water is high and the degree of corrosion is high, so it cannot be reused.

4. The pre-treatment sewage accounts for 75% of the sewage discharge of the entire printing and dyeing process, and due to the complex material composition of the pre-treatment waste liquid, it cannot be recycled after treatment.

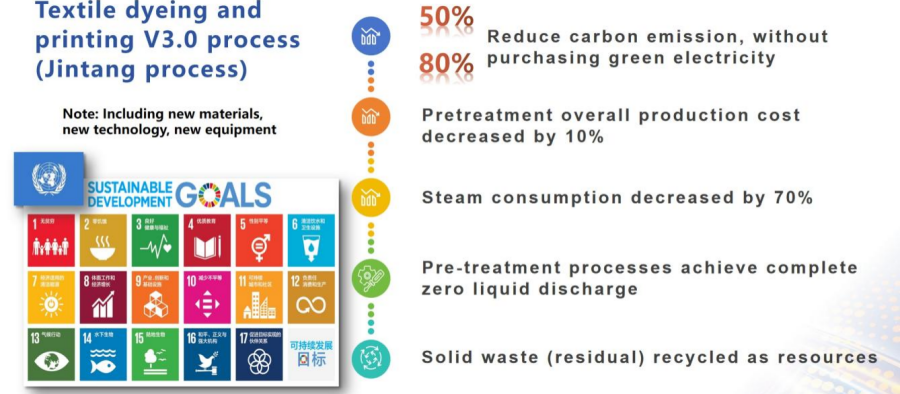

According to Jintang Textile Printing and Dyeing 3.0 system technology, The set indicators, on the premise of improving the quality of the company’s products, It is possible to reduce carbon emissions by more than 50% in the entire printing and dyeing production process(Carbon emissions of the whole life cycle of textiles from cotton to marketed clothing, 70% of which are printed and dyed). This will achieve carbon reduction for all textile enterprises and even the entire textile industry. It provides a strong guarantee.

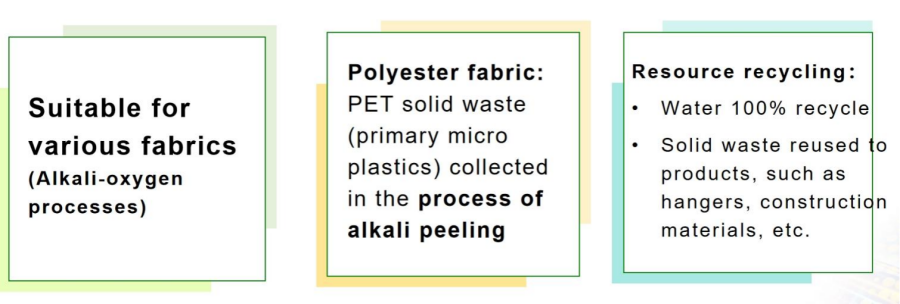

The V3.0 process of Jintang textile printing and dyeing can meet the requirements of all kinds of fabrics. It includes the requirements for high-quality products in the pretreatment of all fabrics such as woven fabrics, knitted fabrics, cotton fabrics and linen fabrics.

Video on the V3.0 pretreatment process.